[ad_1]

|

Take heed to this text |

Sponsored By

Manufacturing amenities proceed to extend their ranges of automation to cut back prices, enhance productiveness, and improve operational effectivity. Newer types of automation expertise additionally present producers with a excessive diploma of flexibility, a functionality missing in lots of earlier types of fastened, or ‘arduous’, automation.

These versatile automation options are being embraced by producers as a key strategic differentiator and enterprise facilitator. For right now’s producers, “flexibility is the brand new productiveness”.

Manufacturing Automation

Manufacturing automation can take many kinds. Using reprogrammable, articulated robots, and now together with collaborative robots, for purposes reminiscent of welding, portray, and palletizing is frequent amongst producers of all kinds and sizes, and different use circumstances like conducting high quality checks utilizing robotic imaginative and prescient inspection programs proceed to develop. One other manufacturing automation mainstay includes using applied sciences for conveyance, the act of transporting supplies, components and different objects, in addition to shifting objects underneath building in meeting traces for sequential manufacturing processes.

Conveyance Automation Varieties

In broad phrases, automation options for manufacturing conveyance are of two sorts – Mounted Conveyance Methods and Versatile Conveyance Methods.

- Mounted Conveyance Methods – As their names implies, fastened conveyance programs are automation applied sciences which can be immovable as soon as in place, or can solely be redeployed on the expense of disruption and nice price. Mounted conveyance programs reminiscent of belts, rollers, and overhead conveyors, present manufactures with productiveness advantages, however on the expense of flexibility. Towline conveyors (see under), generally used for shifting heavy masses in manufacturing amenities, are one other type of fastened conveyance answer.

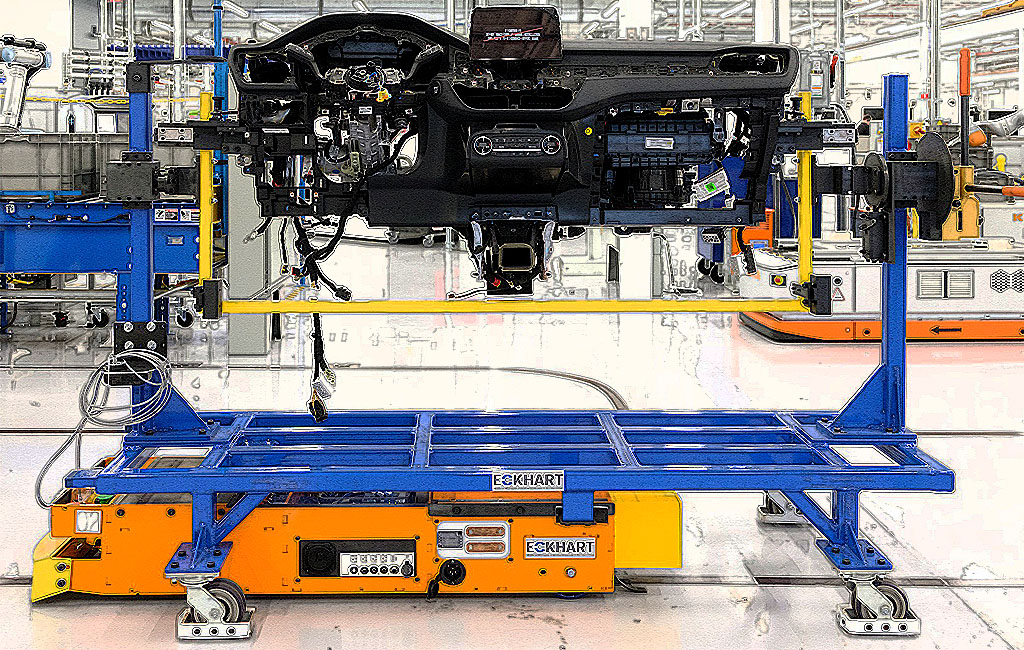

- Versatile Conveyance Methods – Automation applied sciences that may be flexibly redeployed as soon as put in, reminiscent of Automated Guided Autos and Autonomous Cell Robotics (see under), have discovered extensive use in purposes like delivering kitted supplies to point-of-use on an meeting line, in addition to transporting product like vehicles, vans, and tractors by way of their meeting processes. Autonomous cellular robots are generally used as a substitute for fork vans and sometimes tasked with transporting parts as a part of lineside replenishment operations for electrical car, agricultural gear, and medical system producers. Automated guided automobiles have seen extensive adoption amongst producers of heavyweight merchandise due to the security benefits that include automation applied sciences over handbook choices.

Conveyance Automation

Previous to the event of automated conveyance options, objects underneath manufacture have been sometimes transported manually utilizing carts, trolleys or forklifts, each powered and unpowered. Over time, many of those handbook conveyance platforms – inefficient and infrequently harmful – have been automated utilizing quite a lot of system sorts together with:

- Towline Conveyors – Conveyors have been employed in manufacturing crops for over 100 years. One type of these programs, towline conveyors (tow conveyors, towveyors, construct line conveyors, trac-veyors), have discovered extensive use for manufacturing processes that require fixed ahead movement for progressive operations. The vast majority of towline conveyor programs in manufacturing environments use a recessed towline (normally a sequence) to drag wheeled carts alongside a set path by way of sequential workstations.

The event of towline programs requires substantial building and engineering of their operational surroundings. Deep trenching within the ground and intensive concrete / civil work is commonly required. Reconfiguring conventional chain-based towlines in response to altering enterprise necessities is a really labor-intensive, expensive and prolonged enterprise.

AGVs transfer with exactly calibrated acceleration and deceleration, and make use of totally different sensing applied sciences to detect individuals and obstacles, slowing down or stopping relying on how close to the article is, and resuming once more when the trail is evident.

- Automated Guided Autos (AGVs) – Automated guided automobiles (AGVs), are cellular robots that use magnetic tape, RFID tags, optical strips, lasers, or different modalities to information them by way of amenities alongside pre-determined pathways. AGV navigation paths will be altered with relative ease by relocating the guides that management the programs. Modalities like magnetic tape signify the bottom price, however highest upkeep method to navigation.

AGVs are a standard (and confirmed) type of robotic conveyance in manufacturing environments for purposes reminiscent of components and parts supply. Since AGVs are designed to maneuver repeatedly alongside a set path, it additionally makes them extraordinarily nicely suited as a alternative for conventional conveyor programs for work-in-process motion throughout manufacturing operations. Additional, since every AGV unit will be individually managed, it’s attainable to de-couple the meeting line. For instance, some producers strategically plan for buffers, queue positions, or in-process kanbans (IPKs), to assist easy station-to-station timing imbalances. AGVs, being de-coupled from the unit forward of it, are capable of progress out of a accomplished work station to the buffer to maintain the road shifting if the subsequent station could also be briefly blocked.

Autonomous guided automobiles vary in kind from light-weight ‘tugger’ AGVs that that pull unpowered carts for transporting masses, to heavy obligation, excessive payload programs (‘unit load’ AGVs) that may transport discrete, multi-ton objects. Unit load AGVs are additionally more and more being utilized to transfer heavy merchandise underneath manufacture from one fabrication stage to a different.

AGVs transfer with exactly calibrated acceleration and deceleration, and make use of totally different sensing applied sciences to detect individuals and obstacles, slowing down or stopping relying on how close to the article is, and resuming once more when the trail is evident. Not too long ago, some AGVs have integrated applied sciences reminiscent of vison programs and LiDAR permitting them to navigate autonomously in a fashion just like autonomous cellular robots (see under).

- Autonomous Cell Robots (AMRs) – A comparatively new kind conveyance automation – autonomous cellular robots – have been broadly embraced in warehouses and distribution facilities (DCs) to enhance the effectivity of e-commerce inbound (‘putaway’) and outbound (‘choosing’) achievement operations. Whereas there was a lot dialogue in regards to the use autonomous cellular robots for industrial work, the expertise continues to be within the comparatively early phases of adoption. In manufacturing settings, frequent AMR purposes embody using deck-load cellular robots to ship parts and subassemblies to workstations, or as tuggers for light-weight carts.

AMRs navigate autonomous utilizing quite a lot of sensors and sensing applied sciences together with LiDAR (2D or 3D) and digital camera programs (once more, 2D or 3D), with many using each, plus another sorts of proximity sensors. AMRs make the most of their sensors to detect its environment and select probably the most environment friendly path to the goal. It really works utterly autonomously, and if forklifts, pallets, individuals, or different obstacles happen in entrance of it, the AMR will safely maneuver round them, utilizing the perfect various route.

For producers, growing ‘security’ is positively linked to numerous enterprise worth drivers. Examples embody improved employee retention, decrease operational prices, and elevated manufacturing effectivity.

Choice Standards

Many elements have to be thought of when deciding on manufacturing conveyance automation options, together with the next vital parts:

- Capability – Within the context of producing conveyance automation, capability refers to 2 distinct properties:

- Payload Capability – Payload capability refers back to the whole quantity of weight that towline carts, AGVs an AMRs can carry. At the moment, the payload capability of towline and AGV conveyance platforms exceed that of autonomous cellular robots. For heavy load manufacturing operations, the place the components and objects underneath meeting usually exceed 10,000 lbs., high-capacity towline options and AGVs are the one selection.

- Towing Capability – Towing capability denotes to the quantity of load weight towline conveyors, AGVs and AMRs can pull.

- Flexibility – With a view to reply to altering enterprise necessities and fluctuations in demand, producers are inserting larger emphasis on versatile conveyance programs, and eschewing options that depend on ‘arduous’ automation and costly, fastened infrastructure. Producers are more and more trying to keep away from new tasks with intensive civil work that can “lock in” their facility format for years to come back. Conveyance programs differ on their degree of assist for flexibility which may take many kinds together with:

-

- Deployment Flexibility – The power to deploy manufacturing conveyance programs quickly and at low price, is a key requirement for right now’s agile producers. Manufactures must also be capable to redeploy or relocate conveyance automation options inside manufacturing websites with minimal operational disruption and price.

- Software Flexibility – Software flexibility refers back to the skill to repurpose conveyance platforms for various purposes, processes, or operations. For instance, most AGVs are customizable in order that they are often modified to satisfy particular utility wants or ergonomic necessities. Widespread customizations embody the addition of load dealing with service frames, carry decks, scissor lifts, powered trunnions, and turntables.

- Scaling Flexibility – Scaling flexibility refers back to the capability to extend or lower the variety of operational conveyance programs relying on want. For instance, when utilizing automated guided automobiles for sequential manufacturing operations, workflow will be elevated or decreased simply by including or eradicating AGVS from the road. For producers which have demand that’s seasonal or tough to foretell, addition or subtraction of workstations.

-

- Security – Security is vital driver for growing ranges of conveyance automation in manufacturing websites and elsewhere. In comparison with handbook programs, for instance, AGVs have confirmed to cut back employee damage, and reduce injury to components, merchandise, and infrastructure. They’ll detect objects in operational vary and gradual to cease or keep away from them. Methods are additionally outfitted with security edges and bumpers, together with anticipatory warning programs utilizing lights and sounds to let staff know of their method.

For producers, growing ‘security’ is positively linked to numerous enterprise worth drivers. Examples embody improved employee retention, decrease operational prices, and elevated manufacturing effectivity.

- Effectivity and High quality – For producers, improved productiveness – growing the amount of the merchandise they ship – is commonly given as major profit for automating their manufacturing processes. Whereas true, just isn’t the entire story. Growing effectivity, that’s, growing the effectiveness of producing operations, in addition to enhancing and the standard of the objects produced (whereas minimizing prices), is equally vital.

Conveyance options reminiscent of automated guided automobiles are usually not automation islands. In manufacturing websites, fleets of AGVs are monitored and managed by subtle software program, and infrequently linked to warehouse administration programs (WMS) and Manufacturing Execution Methods (MES). AGV administration software program can dynamically reply to suggestions from manufacturing traces to enhance operational effectivity by optimizing efficiency, streamlining workflows, and eliminating chokepoints. Software program reminiscent of Ignition, Wonderware, Aveva, and PLEX present directives to an AGV fleet each wirelessly and thru commonplace Allen-Bradley or Siemens PLCs.

Using autonomous guided automobiles in manufacturing environments has been confirmed to extend the consistency and reliability of operations, which has a constructive affect on high quality of produced items. AGVs present autonomous and reliable point-to-point transportation of products and materials, and by doing so, it dramatically reduces the potential for human error, the first supply of business accidents and injury to merchandise, amenities and extra. Moreover, since AGVs are programmatically managed, and extremely built-in with governing software program programs, the AGV items will be programmed to solely transfer if particular high quality standards are met, successfully serving as an in-station poka-yoke.

Many producers have to convey and assemble merchandise that weigh 20,000 lbs, 30,000 lbs, and as much as 50,000 lbs, however AGVs with capability on this vary are uncommon.

Automating Heavy Load Conveyance

For industries, reminiscent of the electrical car, aerospace, various power, and protection sectors, manufacturing processes usually contain the motion of heavy components, objects in work, and ultimately, completed merchandise. As such, the capability of conveyance automation programs for these producers should usually exceed 10,000 lbs. Many producers have to convey and assemble merchandise that weigh 20,000 lbs, 30,000 lbs, and as much as 50,000 lbs, however AGVs with capability on this vary are uncommon. The distinctive load necessities for these ‘heavy’ producers, could be very totally different for different courses of producers, and is a key differentiator when evaluating conveyance automation options.

AGVs Vs Towlines

Excessive payload AGVs and towlines each share the power to maneuver heavy objects sequentially alongside manufacturing worklines. Automated information automobiles, nonetheless, have distinct benefits over older towline approaches. AGVs, for instance, will be deployed with out the excessive price of constructing the fastened towline infrastructure, together with the entrenching required for embedding the towline itself.

Automated guided automobiles additionally present for a lot larger ranges of flexibility in comparison with towline conveyers. Manufacturing traces will be put in quickly and modified simply to satisfy the calls for of periodically altering meeting traces in accordance with agile strategies.

AGVs vs AMRS

Automated guided automobiles and autonomous cellular robots present manufactures with many benefits over towline conveyance options. Every ship excessive ranges of flexibility and security. AGVs and AMRs deployments may also scaled as want dictates. Nevertheless, the distinctive capability necessities for heavy load manufacturing – 10,000 lbs. and larger – locations AMRs at a definite drawback as an automatic transportation choice for this class of manufacturing. For security, a ultraheavy product ought to sometimes be assigned to a predefined and glued journey path with out latitude given to a navigation expertise to determine and choose various routes.

Better of Each Worlds

Producers are more and more turning to automation and robotics applied sciences to handle the numerous new challenges introduced on by speedy enterprise change, sector development and elevated competitors. This consists of producers within the medical system (assume MRIs), business truck, spaceflight, leisure automobiles, and different heavy industries.

Previously, these producers turned to towline programs to automate their manufacturing traces. Towline programs, strong and succesful for shifting heavy masses, lack the pliability inherent in additional trendy automated conveyance options reminiscent of AGVs and AMRs.

Autonomous cellular robots, a comparatively current addition to producer’s answer set, are famous for offering excessive ranges of deployment flexibility, utility flexibility, and scaling flexibility. Whereas these programs ship worth as transportation platforms in manufacturing amenities and warehouses, their payload and towing capacities fall brief for prodcution workflows that demand the motion of heavy masses.

Trendy automated guided automobiles mix the capabilities set of autonomous cellular robots – flexibility, security and scalability – with the load capability of towline conveyors. As such, they supply producers with the perfect of each worlds, an economical, versatile, heavy load conveyance answer for manufacturing construct traces designed for manufacturing as it’s achieved right now, and that may meet the manufacturing calls for of tomorrow.

Sponsored content material by EckhartUSA.com

In regards to the Creator Dan Kara is Vice President, Robotics at WTWH Media the place he chartered with driving the corporate’s robotics initiatives together with the Robotic Report and Robotics Enterprise Evaluation on-line portals and the Robotics Summit Convention and Exposition, Healthcare Robotics Engineering Discussion board, RoboBusiness Convention & Expo and the Worldwide Subject Robotics Engineering Discussion board. Previous to becoming a member of WTWH, he was Observe Director, Robotics and Clever Methods at ABI Analysis. Dan was additionally President of Robotics Developments, an built-in media and analysis agency serving the private, service and industrial robotics markets. Dan has additionally labored as Government Vice President of Intermedia Group, and Director of Analysis at Ullo Worldwide.

Dan Kara is Vice President, Robotics at WTWH Media the place he chartered with driving the corporate’s robotics initiatives together with the Robotic Report and Robotics Enterprise Evaluation on-line portals and the Robotics Summit Convention and Exposition, Healthcare Robotics Engineering Discussion board, RoboBusiness Convention & Expo and the Worldwide Subject Robotics Engineering Discussion board. Previous to becoming a member of WTWH, he was Observe Director, Robotics and Clever Methods at ABI Analysis. Dan was additionally President of Robotics Developments, an built-in media and analysis agency serving the private, service and industrial robotics markets. Dan has additionally labored as Government Vice President of Intermedia Group, and Director of Analysis at Ullo Worldwide.

[ad_2]